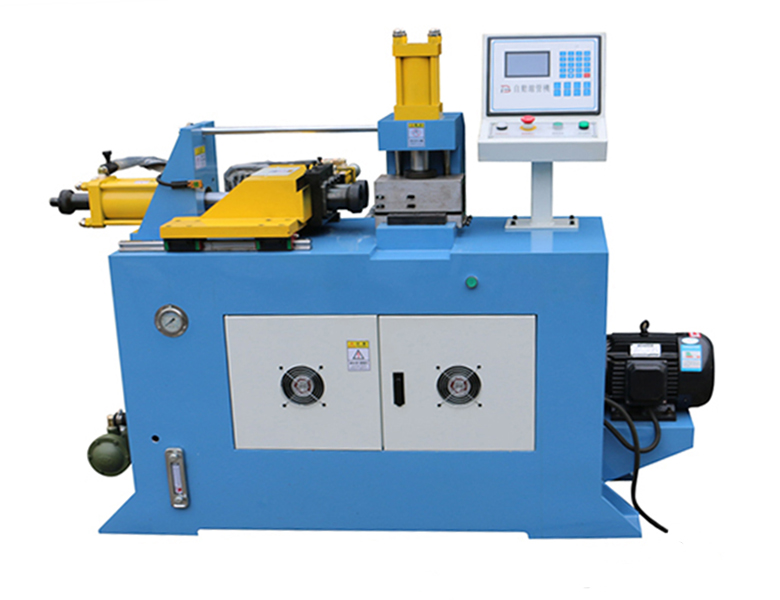

The tube end-forming process is where tube ends are flared, reduced, and shaped using a tube end-forming machine. With years of experience and expertise in the metal tube processing industry, KEENSAW’s range of tube end-formers allows you to specify and meet many shapes like swaging, reduction, expansion, flaring, flanging, beading, bulging, chamfering, rounding, tapering, and many other designs.

Our end forming machine is highly utilized by different industries like automotive, construction, motorcycle, air conditioner, lighting, fitness equipment, medical, and other engineering industries. Whatever industry you belong to, the KEENSAW tube end forming machine will surely be of use.

Our machines can work on different materials, such as stainless steel, carbon steel, mild steel, copper, brass, aluminum, alloys, nickels, and titanium. You name it, just about any metal.

As a professional tube end forming machine manufacturer, we can help you troubleshoot errors and help you achieve high repeatability and accuracy, consistent finished parts, which are with critical tolerances, concentricity, and offsets.

Our clients are satisfied with their KEENSAW machines and give us positive feedback. Contact us to be a KEENSAW tube end forming machine owner now!

KEENSAW tube end former can help you form various end shapes, below are the common ones.

Tube beading is a tube end forming process that creates a bead on the end of a tube. It is the most popular end-forming type.

The tube end outer diameter (OD) is increased/stretched. Expanding tube ends is important when connecting tube ends to other parts or assemblies.

Tube reducing is a tube end process that reduces the tube end outer diameter(OD) to fit into the inside diameter(ID) of the same tube or similar opening.

Round tube ends to make it more smooth when insert it into another tube with same diameter.

Flaring the tube to 90-degree is a flange.

Tube flanging is an end-forming process designed to provide for attachment to other components or hardware.

Tube tapering is produced by means of a two-die or four-die rotary hammering operation. As the tube is fed in, the tooling revolves around the work piece while moving in and out.

Lishui Keensaw Machine Co., Ltd is a one-stop metal cutting solutions specialist, mainly manufacture cnc carbide circular saws, band saws, tube cutting machines, non-ferous metal sawing machines, chamfering machine, and supply TCT saw blade, HSS saw blade and Bi-metal band saw blade to our customers.

Contact us if you have any questions we will reply as soon aspossible